ABB Freelance DCS

ABB's Freelance, the distributed control system for process applications, combines the best of both worlds, DCS and PLC. It offers PLC size and price with functionality of a DCS. The integrated environment facilitates engineering, commissioning, maintenance and fieldbus management. The intuitive operator interface enables easy operation and diagnostics of the entire system.

Freelance is proven in more than 15,000 applications - in all industries. The easy-to-use control system allows the integration of all common fieldbuses, leaving the user to select any they wish - whether it is FOUNDATION Fieldbus, PROFIBUS, or HART. The system was and will be continuously improved and enhanced to meet our user's needs. Customers choosing Freelance can be rest assured that ABB and Alpha will support them in the long term.

Freelance is proven in more than 15,000 applications - in all industries. The easy-to-use control system allows the integration of all common fieldbuses, leaving the user to select any they wish - whether it is FOUNDATION Fieldbus, PROFIBUS, or HART. The system was and will be continuously improved and enhanced to meet our user's needs. Customers choosing Freelance can be rest assured that ABB and Alpha will support them in the long term.

ABB 800xA Extended Automation DCS

System 800xA is ABB's flagship Collaborative Process Automations System offering to all of the major industrial process manufacturing and utility markets. 800xA is the best, most capable, reliable process automation system available. Imagine a system where with one click and operator could access any information required to make an informed decision regardless of where it resides, or a maintenance technician could access device commissioning displays, documentation, current health status and a list of active work orders.

ABB Compact HMI SCADA

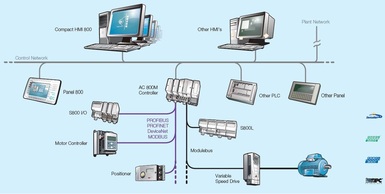

The Compact HMI 800 is a comprehensive HMI that is delivered ready to be used out of the box. A delivery includes both hardware and software, the software is installed in one or more PCs which are ready to be powered-up and then the system is running. A Compact HMI 800 system consists of the following main parts, One Server Workplace with Operation and Engineering functionality and up to nine Additional Clients with Operation functionality.

PROGRAMMABLE LOGIC CONTROLLER (PLC)

Optimized processes, minimized costs, higher profitability – the AC500 offers you a maximum of options for ensuring that crucial bit of extra added value. The wide choice of communication couplers enables you to customize the automation system to suit your own individual requirements. Thanks to the AC500’s scalability and its modularized platform concept, you can configure precisely the automation system you need. It’s these unique advantages that render the AC500 so enormously cost-efficient, safe and user-friendly.

The AC500 – persuasive advantages

• Scalable control

• Wide choice of communication and field bus couplers

• User-selectable coupler types for simultaneous operation

• Fast replacement thanks to plug-in modules

• A single software package for the entire range

• Seamless integration of control system and field devices

• Attractive price-performance ratio

Profit from maximized solution multiplicity

The AC500 completely redefines the term “flexibility”. By virtue of its up-to-the-future field bus plug technology, the field-bus-neutral system can be easily connected up to almost any desired field bus. Its scalability offers a maximized multiplicity of solutions for accurate handling of every automation job – all that’s needed is a quick replacement of the CPU or simply 5 expansion using I/O modules. ABB has thus met its customers’ forceful requests for individually tailored automation systems, with concomitant enhancement of market opportunities and growth potentials.

The small number of modules means fewer spare parts and correspondingly low storage costs. Since only one standardized software package and consistently harmonized hardware are used for the entire AC500 range, the outlay for software, training and support is reduced to a minimum – intelligence that pays off for you!

The AC500 – persuasive advantages

• Scalable control

• Wide choice of communication and field bus couplers

• User-selectable coupler types for simultaneous operation

• Fast replacement thanks to plug-in modules

• A single software package for the entire range

• Seamless integration of control system and field devices

• Attractive price-performance ratio

Profit from maximized solution multiplicity

The AC500 completely redefines the term “flexibility”. By virtue of its up-to-the-future field bus plug technology, the field-bus-neutral system can be easily connected up to almost any desired field bus. Its scalability offers a maximized multiplicity of solutions for accurate handling of every automation job – all that’s needed is a quick replacement of the CPU or simply 5 expansion using I/O modules. ABB has thus met its customers’ forceful requests for individually tailored automation systems, with concomitant enhancement of market opportunities and growth potentials.

The small number of modules means fewer spare parts and correspondingly low storage costs. Since only one standardized software package and consistently harmonized hardware are used for the entire AC500 range, the outlay for software, training and support is reduced to a minimum – intelligence that pays off for you!